Engine mount brackets by JTR;

Engine mount brackets by JTR;

Last edited by BRAAP; 04-26-2010 at 12:09 AM.

That is sweet project,looking forward to seeing it run

2008 Trailblazer SS 2wd red jewel 1ss

Forged 365,Tvs1900@11psi,IW 8 rib overdrive,duel pass heat ex,Prc heads,blower cam,Yank,Aeromotive,ect

Well... yes, and no... It's nice to have them for mocking up the LSx in various chassis in hopes a stock manifold just might fit. LS1/6 C5 Vette, LS2/3 C-6 Vette, Caddy CTS-V, LS1/2 GTO, F-body, and truck.

Thank you. I am also looking forward to seeing this run, hopefully soon...

BREAK THROUGH on the clutch line!

Short version;

OE GM LSx clutch line fits the BMW master cylinder with a small massage, no need to buy fittings, cut the GM clutch line, etc...

Only thing needed to buy other than your slave cylinder is a remote bleeder line/kit like the one from TICKshift.com.

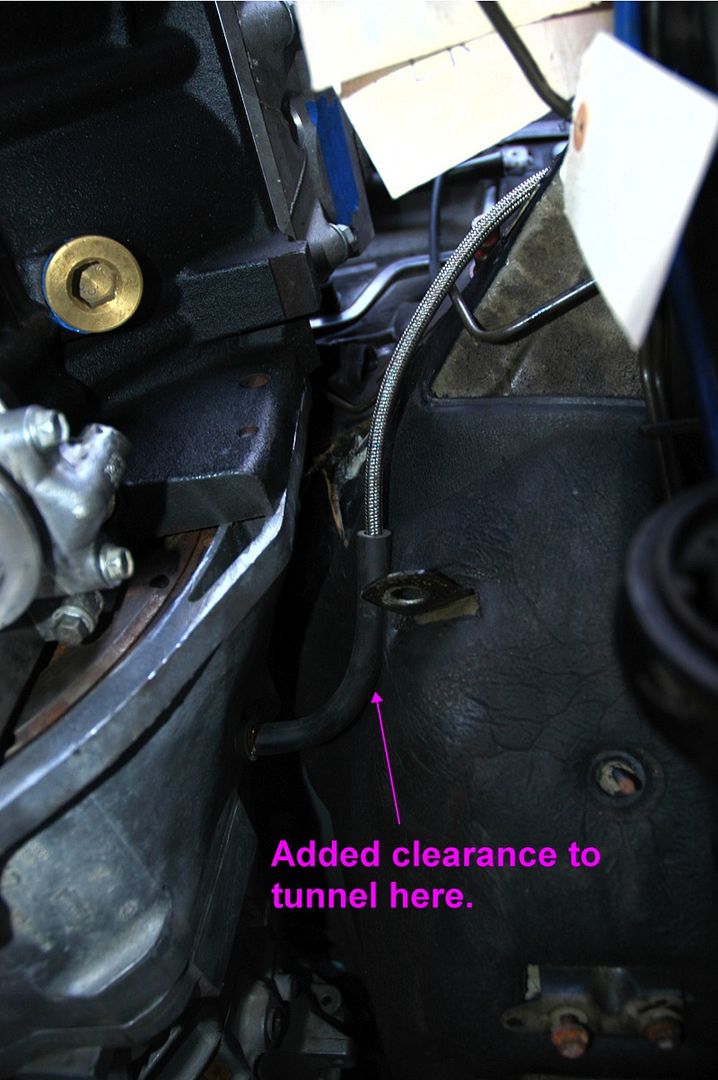

I did hammer the tunnel about 3/4" deep trough where the clutch line comes out of the bell-housing to relax the bend on the clutch line, fits nice in the tunnel.

Long version;

Yesterday in finishing up the clutch lines, I was going to go the typical route and cut the GM clutch line, install the -4 fitting, use the -4 to 10mmx1.0mm ISO bubble flare fitting, yadda yadda yadda, but with the GM clutch hose hooked up the trans I noticed its length is absolutely perfect in that it reaches the BMW master cylinder. I got to looking at the BMW master cylinder connection a little closer, removed the hard line retaining clip and wiggled the hard line out of the M/C and thought about what it might take to get the GM clutch line to plug into the BMW Master Cylinder. Spent some time measuring up both the GM and BMW master cylinder connection bores, then the GM and BMW clutch line fittings, sketched them out in AutoCAD and came to the conclusion it can be done. The BMW M/C bore is smooth at the O-ring diameter for what looks like all the way to the piston so the GM fitting could sit at any depth past the minimum. So I chucked the GM clutch line in the lathe and machined .020" off the diameter of the GM fitting as shown below and added a .040" tall chamfer to allow it to sit deep enough into the M/C to accept the BMW retaining clip and that's it, fits PERFECT! Using the GM O-ring, (BMW O-ring will not fit the GM fitting), it ends up compressing a total of .021” more than it does in the GM M/C, (tighter fit), not so much it causes any issues wit sealing, over squishing, etc. Surprising part is with a little brake fluid on the O-ring it doesn’t feel any tighter when installing it. Installed and removed several times to verify fitment. Best part is the GM clutch line is already the perfect length!

Here are the drawings and pics, enjoy…

BMW Master Cylinder connection detail;

GM LSx Master Cylinder connection detail;

Hybrid LSx line-BMW Master Cylinder;

3D render of the Hybrid connection.

Retaining clip fits perfectly behind the crimped fitting;

Prior to installation;

INSTALLED! Retaining clip holds it firmly, wont go in any deeper or come out and it is already the PERFECT length! SAH-WEEET…

Last edited by BRAAP; 05-07-2010 at 10:38 AM. Reason: Added 3d rendering.

Wow! I have to say that I am more impressed than I have been in a long time. I have seen a lot of swaps, strange ones at that, and that it sounds like you can easily get this done with all of the details worked out. Not just throwing it in there and it just hanging by a string.. Cant wait to see this done!

5.3, small cam, 918 springs, 7.4 rods, walboro pump, Full built 4l60, 2800-3000 stall, TB spacer, long tubes, cat delete, single 3" exhaust with Aero bullit muffler. Flaco tuned.

Overall, this project is actually supposed to be quite easy to replicate, not only for myself if the car gets damaged, but this conversion is a prototype conversion kit that will be available from Jags That Run this summer;

Stealth Conversions BMW V8 Parts

... for others to be able to “bolt-in” an LSx into their BMW E36 car, (’92-’99 3 series), including the brake booster spacer, mounts, driveline adaptor, radiator hose connectors, etc. Of course the conversion will require the installer to utilize readily available local resources that any garage tinker would normally utilize for his/her small projects, such as adapting the P/S lines from GM pump to BMW rack or just order the fittings and assemble his/her self, etc. The clutch line fitting is a used Camaro/Firebird clutch line with simple massage to the outside diameter of the fitting that inserts to the Clutch master cylinder, not a “one-off" custom part.

And example of a custom one-off car project that would suck if the car was ever damaged is my best friends Datsun 510 project that he recently sold. He installed an SR20DET engine which was that bad, even with the custom X-member for the engine, (could be built again if needed and bolts to the car). He also converted the complete front suspension and recirc-ball steering over to BMW E30 with power rack and pinion and much more aggressive suspension geometery;

510 (Bart), SR20DET powered w/BMW suspension - HybridZ

That meant cutting out the strut towers, building from scratch brand new strut towers, custom modified body frame rails for the different lower control arm mounting, connecting the BMW rack to the Datsun steering shaft, etc. Lots of custom one off parts that if he wrecked the car would not be easy to replicate, nor would he want too.

Having done more than few engine conversions over the years, one thing that I am focusing on is being able to replicate the parts and labor whether I build another for myself, wife, friend, or need to replace this one for any reason and do so with as little compromise as possible. Being a machinist and having a mill and lathe in my shop helps, at that there really aren’t many custom machined one-off components that would be hard to replicate even if I didn’t have access to a machine shop. The specific conversion components are available from JTR.

With the engine and trans just sitting in the car, using a remote reservoir, filled the clutch line, bled the clutch and wa-la, got clutch action and NO leaks! Clutch pedal “feels” pretty good, though wont for sure until the engine is running. Pedal pressure starts right off the top, has a slight ramp up in pressure till approx 2/3 pedal down then has a very distinct over-center feel as the pedal effort gets considerably lighter closer to the floor. Overall pedal effort feels about the same as I recall the stock M-3 clutch effort and next to Rons ’98 M-3, is the same but with a more pronounced over-center feel.

Spent a bit of the day upgrading my DIY brake pressure bleeder and setting up a BMW M/C reservoir cap for it. Hoping to have the ABS relocated and with new lines brakes done by the end of next week, or sooner. ;-)

Pic from engine bay;

Pic from under the car;

the build looks awesome!! how are u gonna get the exhaust around the steering shaft?