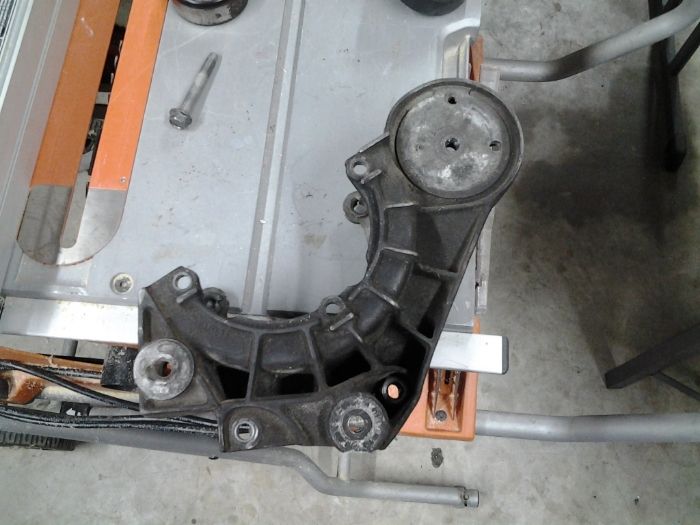

'Jay I used what already came with my truck. I used the round bar braces that were used for the alternator bracket to intake manifold and the 4 wheel drive brackets from the engine mounts down to the transmission torque converter cover. By mixing and matching/cutting/welding, I had all the material I needed from my old engine. I'm an Ironworker by trade, so welding and fabbing anything in steel is not beyond my abilities.

Here's a pic of the 4 wheel drive brackets that have the round bar braces that were utilized for the A/C bracing. They are just to the left of the engine, on the cart.

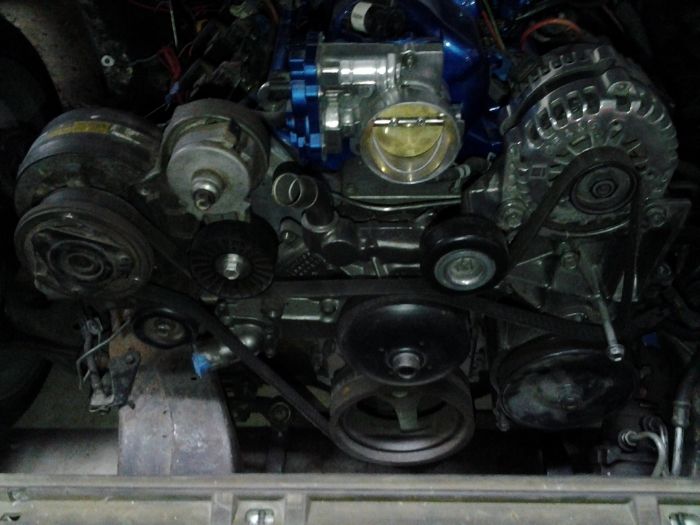

'93 Chevy 1500 4X4 ECLB with a '99 Silverado LQ4 6.0 and '99 Escalade 4L60E. SOLD IT!!

New toy: 2001 2500 HD 4X4 Extended Cab Long Bed

John

Reply With Quote

Reply With Quote