-

Cam lobe failure analyses.

Anyone else see OE cams fail across the nose of the lobe?

Short version ’01 Suburban 1500 4wd, 5.3 LM7, bone stock, NEVER opened up! We are second owners, purchased the Burb at 27,000 miles. It had slight lifter tick since the day we bought it, that never got worse, even to 150,000 miles, so we didn’t worry about. At 150,000 miles a loud "squeak squeak squeak" noise shows up, follows engine RPM. Sounds exactly like a belt squeal. With mechanics stethoscope didn’t take long to narrow down to the middle of the passenger valve cover. Valve cover removed, narrowed down to #4 intake. Remove rocker squeak gone, reinstall rocker squeak comes back. Rocker checks out fine, even swapped with another rocker to narrow down rocker or lifter. #4 intake “lifter” is the culprit. Ok, sounds like the roller of the lifter is sliding across the lobe, i.e. not rolling any more. Found another complete LM7 to swap in, either ’02 or ’04, (pretty sure its an ’04) swapped engines just prior to Thanksgiving, replacement engine runs great, wife is happy she has her rig back. I am currently swapping her old 5.3 into my BMW M3. Swapped in a Vette cam, new lifters, LS1 intake, ported the heads and treated them to a 4 angle valve job. Yet another, BMW E-36 LSx conversion... - LS1TECH

Long version...

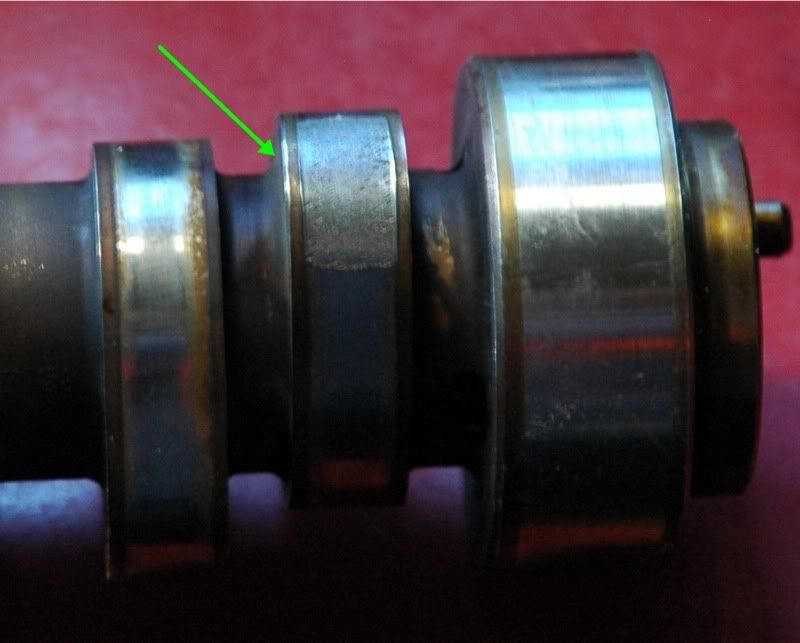

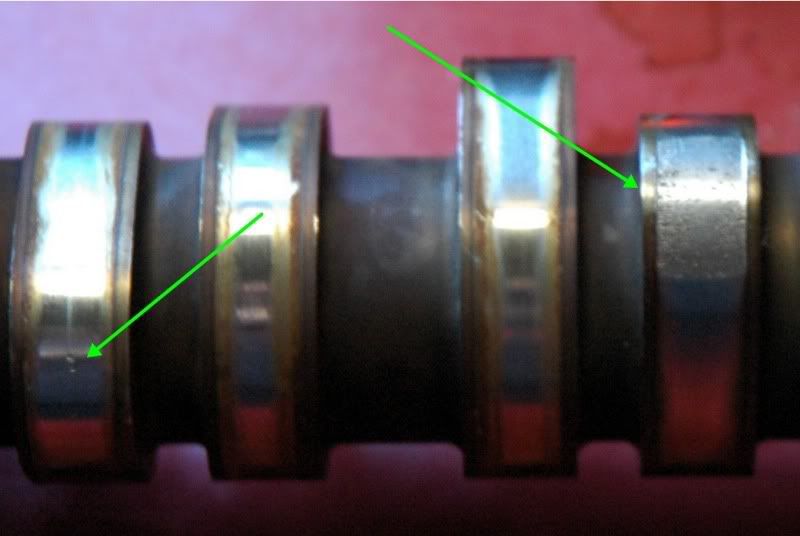

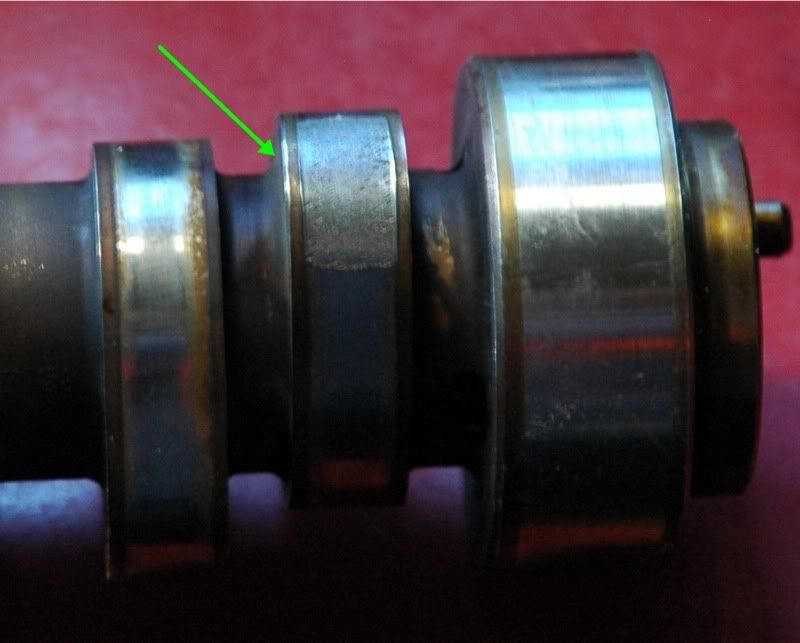

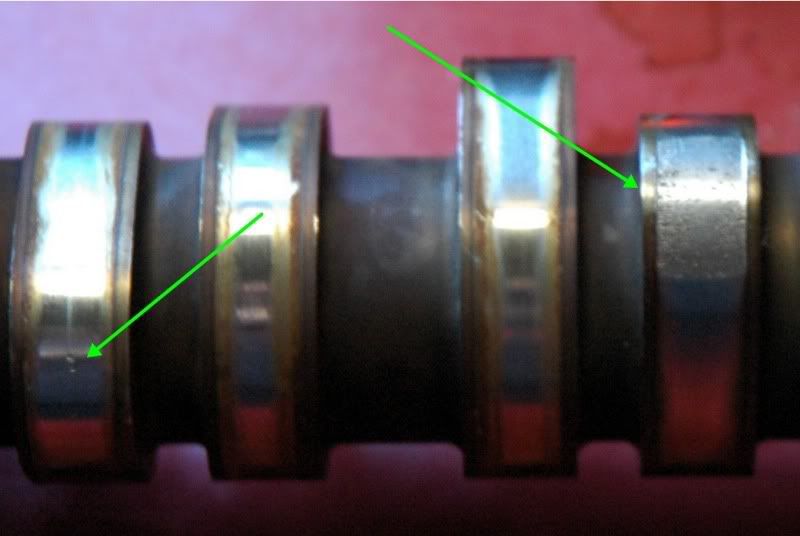

Removed the cam, 3 of the lobes have severe pitting/fatigue, but only over the nose. 3 other lobes starting to pit, again, only across the nose. Lifters ALL still roll just fine, no wobbles, no slop, no grit, the ones off the pitted lobes do have pits on the rollers, #4 intake obviously the worst. I’m a bit confused here?!?! I would expect to see this sort of lobe failure from coil bind. This is a bone stock never opened up LM7, as such, should not be experiencing coil bind. The opening and closing ramps look fine, i.e. no signs of valve float/bounce or excess loads while opening and closing. The failed portion of the lobe is only across the nose with a slight bias to the closing side, (see below). A few other lobes are showing signs of the same issue, couple pits, across the nose only, on their way to the same failure.

Rollers in the lifters all roll fine. The squeaky lifter, #4 intake, shows signs of the roller sliding across the cam lobe and “severe” pitting on the roller itself, but the roller itself still rolls perfectly fine, no slop, no wobble, no grinding, etc. Feels just like the brand new set of LS6 “crate motor take-out” lifters I just bought?!?!

Interesting the failure is across nose of the lobe where unit loading across the lobe is reducing during operation. I would think the cam would fatigue/pit at the point of greatest dynamic loading, such as the start of the opening ramp or on the closing ramp where the lifter is slowing down!

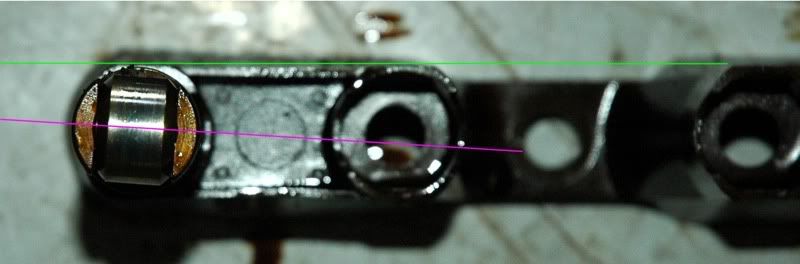

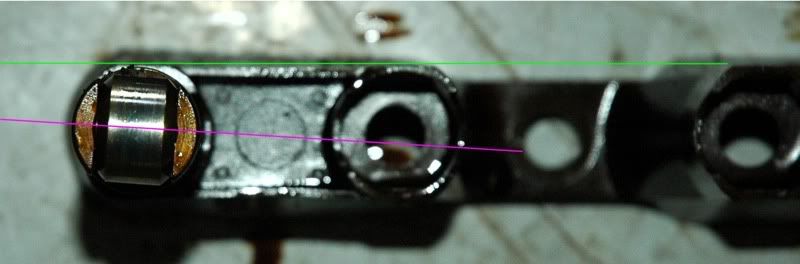

Green lines are start and stop of the failure, magenta line is the apex of the lobe.

#4 intake lifter;

I then took a closer look at the lifter trays. When I removed them, I did not witness them for position or orientation, my bad. What I did find was interesting. One tray is a #9, two are #10’s, and one is #11. Lifters fall into their slots in the trays, some do allow just a very slight amount of rotation, maybe between 1-2 degrees? Not as much as I thought might be present.

Just as someone else pointed out on another forum, the #10 trays do not have the flats aligned square to the cam! They are very noticeably off!

Something else I will be taking a closer look at are the valve springs. This being evident on the intakes only got me thinking. It could just be coincidence it is the intakes only, but the intake valves are heavier and if the springs are weakening, at elevated RPM’s the lifter could be lightly lofting over the nose and in combination with the lifter not rolling true across the lobe, possibly “chattering” as they roll/slide over the nose?

At any rate, I need to track down the GM specs for valve spring pressures on the seat and over the nose. I will disassemble the heads and measure the spring pressures at those 2 points and report back. Anyone by chance have a factory service manual with those figures for an '01 LM7 5.3? Cam is the 0967 grind.

For now, here are the trays;

Looking closer at the #4 intake lifter, the shine on the edge of the flats indicates that the cam was doing its best to straighten out the lifter.

Also, the lifter slots with the worst twist in the #10 trays are VERY lose around the lifter within the lifter travel of the tray and have significantly more rotation than the others.

Disassembled the heads. Haven’t been able to find service limts in regards to LM7 valve springs seat and over the nose spring pressures.

Installed spring heights measured consistent 1.790”-1.795”

All springs compressed to 1.795” for seat pressure; 70-75 lbs.

Intake compressed to 1.335”; 200-210 lbs(1.338” is calculated compressed height for .457” lift)

Exhaust compressed to 1.330”; 195-205 lbs (1.329” is calculated compressed height for .466” lift)

So possible culprits thus far;

1) Bad cam core, (soft/improper hardening, etc).

2) Lifters not tracking true on the cam lobe.

3) Possible soft springs, lofting/chattering lifters across nose of lobe (still need spring pressure service limits specs).

4) Combination of any of the above.

5) ???

Last edited by BRAAP; 08-12-2009 at 03:33 PM.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

Forum Rules

Reply With Quote

Reply With Quote