First off, I'm not a skilled master mechanic, and I have never done an engine R & R yet, but I feel pretty confident about pulling this swap off with my experience and research that I have done thus far. I've managed to work out a lot of the issues that I'm running into, but let's face it - there is a lot of stuff that has to be adapted and changed out to pull everything together and make it work.

I keep hearing different things from different people who are supportive, as well as dead-set against my endeavors to go through with this swap. Here is a brief list of the different adaptations I will need to do and my thoughts on it. If anyone has any suggestions, please feel free to chime about any of it.

I'm putting a Gen IV, 5.3L LMG and 4l60e (automatic) into my 1988 K5 Blazer, but I'm keeping the Blazer's original transfer case. The 5.3 and 4l60e are stock with the wire harness, CPU, throttle pedal, electric fans, alternator, exhaust manifolds, and such (no exhaust pipes or catalytic converters, but pretty much all other parts).

High Pressure Fuel System: my Blazer has TBI, so it has the baffle tank and metal fuel lines with a return line. I think all I need is the right aftermarket fuel pump and a Corvette fuel filter regulator (PN WIX-33737 - $65 at Summit). I have a few possible fuel pumps to choose from, but I have not determined the right one yet. Does this system seem to be able to support a higher pressure around 60 psi?

Transmission to Transfer Case: the 4l60e is supposed to be nearly identical to the Blazer's 700R4 (in size and shifting points), but the 4l60e is electric, and because of it's bell house, it will not directly attach to the Blazer's 208 transfer case. I spoke to Advanced Adapters about this, and they recommended this adapter - PN 50-0405E (6 bolt to 4 bolt adapter with VSS for the 1997-Current GM 4L60E/4L65E 4 speed automatic transmission). Summit is selling it for about $250.00. The adapter attaches between the 4l60e and the Blazer's original transfer case adapter, and it gives the engine signals about speed, shifting points, etc. Seems pretty easy to install, doesn't cost too much, and the part has been on the market for about ten years without any major complaints.

Motor Mount Plates and Clearance: My research tells me that the LMG oil pan will clear fine for my frame type, but depending on where the 5.3 sits, it might affect the length of the drive line. Several folks who have done nearly this same swap with old K5 Blazers say that the Dirty Dingo mounts (PNDD-2575-4) are the way to go, and that with their adjustable nature, there was no need to mess with the drive line. The 5.3 AC gets in the way, though, and needs to be removed/relocated. I hear the 5.3 exhaust manifolds don't quite clear the frame either. One solution is to trim the frame a bit, and the other option is to find headers that will clear. Several swappers said that the 2010 Camero exhaust manifolds work perfectly. I don't recall where I saw it, but one fellow said he made the Blazer's 5.7 Gen II exhaust manifolds work with the 5.3. I'm pretty sure this will not work, would it?

Air Conditioner: after looking over a lot of AC relocation brackets, I found one that seems most feasible, but the whole set-up is going to cost a little over $500. LSBrackets.com builds a bracket (PN “Turbo” ls-0278) that will allow me to relocate the Blazer's R4 compressor to the top, passenger side of the engine. It will then get in the way of the 5.3 stock air filter unit, but I was going to get a Spectre Intake system and relocate it to the driver side anyway. I will need to buy a new R4 compressor for a 6 rib belt, a new tensioner, and a 6 rib belt. This set-up allows me to recycle and use the Blazer's original AC system.

Steering Column Shiftier and the 4l60e: The Blazer's original shiftier linkage will supposedly not work with the new transmission, but Lokar builds an aftermarket linkage kit that seems like it will work (PN#625-ACA-1800) - Jegs is selling it for about $65. According to Lokar, if you have a straight line from the end of your steering column to the transmission shiftier, then this kit will work well. I do, but I'm a bit worried about the exhaust system getting in the way if I use the stock 5.3 exhaust manifolds.

Speedometer and Gauges: changing this crap out can get real expensive. As much as I want to join the Digital Dakota bandwagon, I don't have the cash right now. The Blazer's stock speedometer should still work fine since I'm keeping the 208 transfer case (the speedometer cable attaches to it). All the Blazer's other gauges should work as well if I have them accounted for in my custom wire harness. I'll probably need new sensors, though. I really don't know much about sensor mods.

Wire harness and CPU Flash: I think someone on this forum might work for Nelson's Performance. That's cool, but I'm not going with Nelson this time. I checked out the prices and itemization costs, and I found something a lot more feasible, here, in Boise. The harness and flash will cost me $650 with all the bells and whistles. Also, if something isn't working right, I'm in the same city as the guy who did the work.

Radiator: Some folks say the Blazer's stock radiator will work fine with the 5.3, and others say I should get something bigger. I'm not sure yet. I know that this is the 2nd radiator for the Blazer, and it's got about 80K on it, so I should probably get something new, and it would be advantageous if the new radiator accepted the 5.3 transmission cooler cables. Any suggestions that don't cost a lot? The folks in this build page http://www.truckinweb.com/tech/1111t.../photo_06.html used a radiator for a 1982 big block 2500. I don't imagine the trans cooler cables will match up with it, though. The price isn't bad.

Power Steering: I hear the 5.3 power steering pump and reservoir don't get in the way of the Blazer's frame at all, and that the Blazer's power steering hoses will work with the 5.3 perfectly. Everyone who did the swap said to be sure to hook everything up before dropping the 5.3 into the truck because there isn't room to spin a wrench once it is in. They also said to be careful and not pinch the hoses in half during the install. A critic of the swap asked me how I would release the pressure from the power steering, and I told him I have no idea what he is talking about. He said that I would need some sort of pressure relief valve. Does anyone have any idea what he is talking about?

Gen IV DBW: I think Drive-By-Wire used to make swaps ugly about five years ago, but most people don't seem to care anymore. I have the accelerator pedal and the necessary cable, so as far as I can tell, I will just need to build a bracket that attaches the 5.3 pedal t the firewall. It's too bad that the newer pedal seems cheap and inferior to the Blazer's heavy-duty stock pedal.

I think this is about it for now. As I start figuring out each conversion, I'll be sure to post pictures and updates. As always, thanks for any help and advise! This forum rocks!

Reply With Quote

Reply With Quote

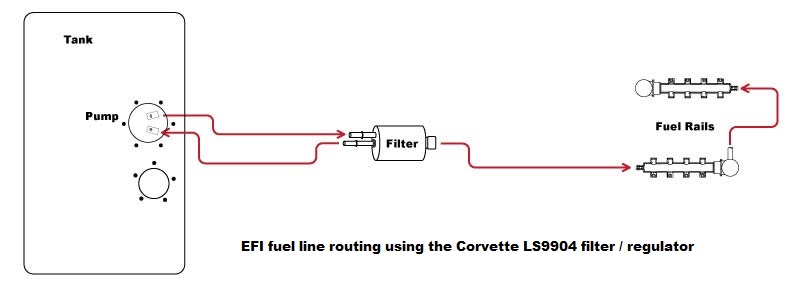

. The website has many other system diagrams if this one does not seem appealing. The "filter" in the image is a Corvette fuel filter/regulator - usually a WIX-33737 for about $45, or you could use a LS9904-KIT from Tanksinc.com for around $70 with the bracket and quick connectors already attached. I’ll keep my tank and fuel sending kit and drop an in-tank pump; either the HFP 255LPH Fuel Pump Chevrolet K10 Pickup 4x4 1988 - 1995 (HFP-343) or the255LPH GM Walbro Alternative Fuel Pump w/ Venturi Tube (HFP-368H). According to the manufactures, both pumps will install without any weird modifications (e.g. cutting, gluing, welding), and they will produce a little over 60psi. My engine will only have about 320 HP, so if you have more HP, you will likely need a different fuel pump and bigger fuel lines. From my pump, I’ll have my supply line leaving my tank and flowing to the Corvette fuel filter/regulator which will be mounted to the side-frame of my truck on the passenger side. From the filter/regulator, one line will return back to the tank, and the other will flow directly to the fuel rail port on the engine. I might include a couple additional micon filters in the circuit as well. Here is a video that show what the fuel supply line will look like. For the first two minutes, the guy just gives a sales pitch, but after that, it becomes visually useful:

. The website has many other system diagrams if this one does not seem appealing. The "filter" in the image is a Corvette fuel filter/regulator - usually a WIX-33737 for about $45, or you could use a LS9904-KIT from Tanksinc.com for around $70 with the bracket and quick connectors already attached. I’ll keep my tank and fuel sending kit and drop an in-tank pump; either the HFP 255LPH Fuel Pump Chevrolet K10 Pickup 4x4 1988 - 1995 (HFP-343) or the255LPH GM Walbro Alternative Fuel Pump w/ Venturi Tube (HFP-368H). According to the manufactures, both pumps will install without any weird modifications (e.g. cutting, gluing, welding), and they will produce a little over 60psi. My engine will only have about 320 HP, so if you have more HP, you will likely need a different fuel pump and bigger fuel lines. From my pump, I’ll have my supply line leaving my tank and flowing to the Corvette fuel filter/regulator which will be mounted to the side-frame of my truck on the passenger side. From the filter/regulator, one line will return back to the tank, and the other will flow directly to the fuel rail port on the engine. I might include a couple additional micon filters in the circuit as well. Here is a video that show what the fuel supply line will look like. For the first two minutes, the guy just gives a sales pitch, but after that, it becomes visually useful: